BÖWE Turbidity measurement for clarity

BÖWE machines are constantly being further developed. One aim is to further improve the energy efficiency of the already first-class machines.

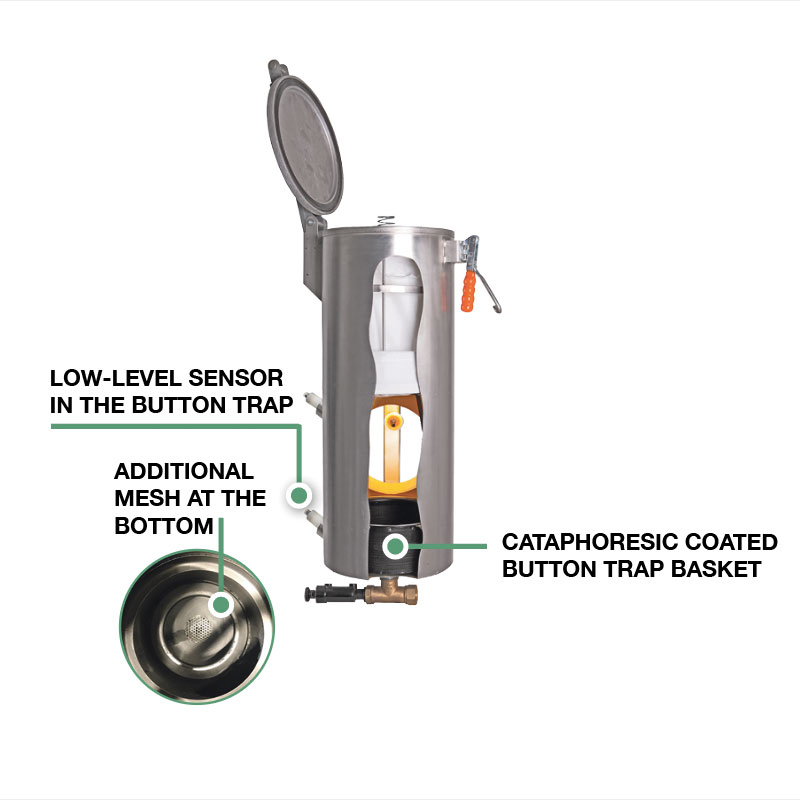

Besides the low-level sensor, adapting the solvent quantity to the amount of garments, BÖWE developed another new energy-reduction feature in the area of environmentally friendly energy management: the turbidity measurement

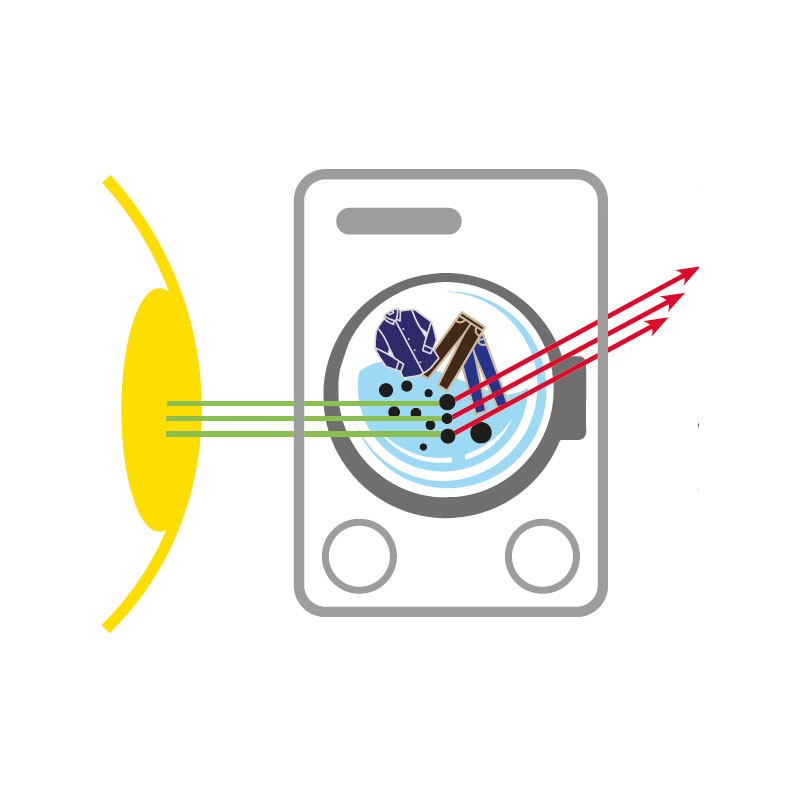

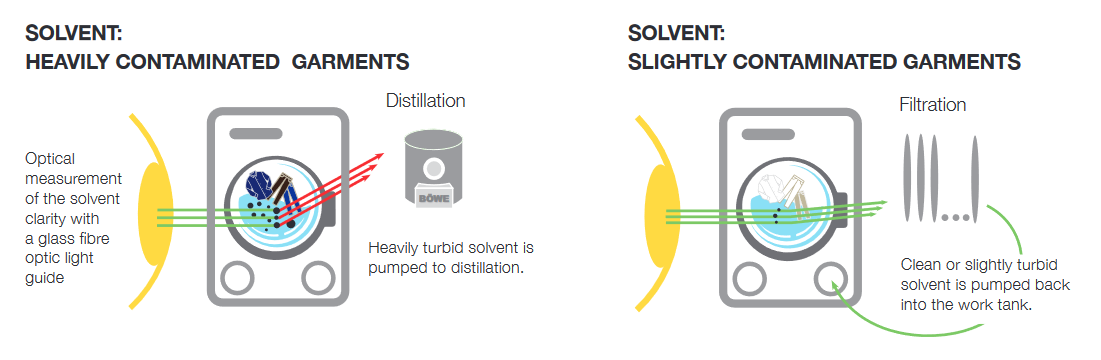

The automatic turbidity measurement

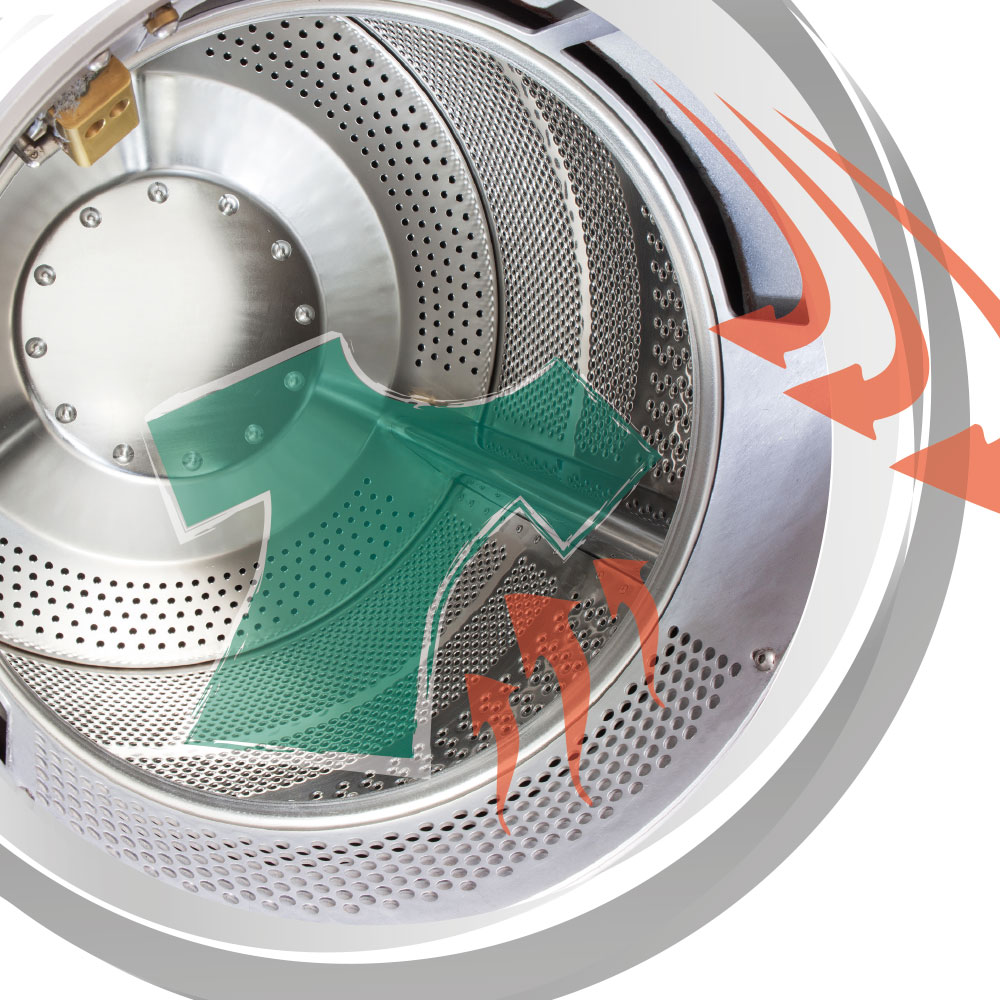

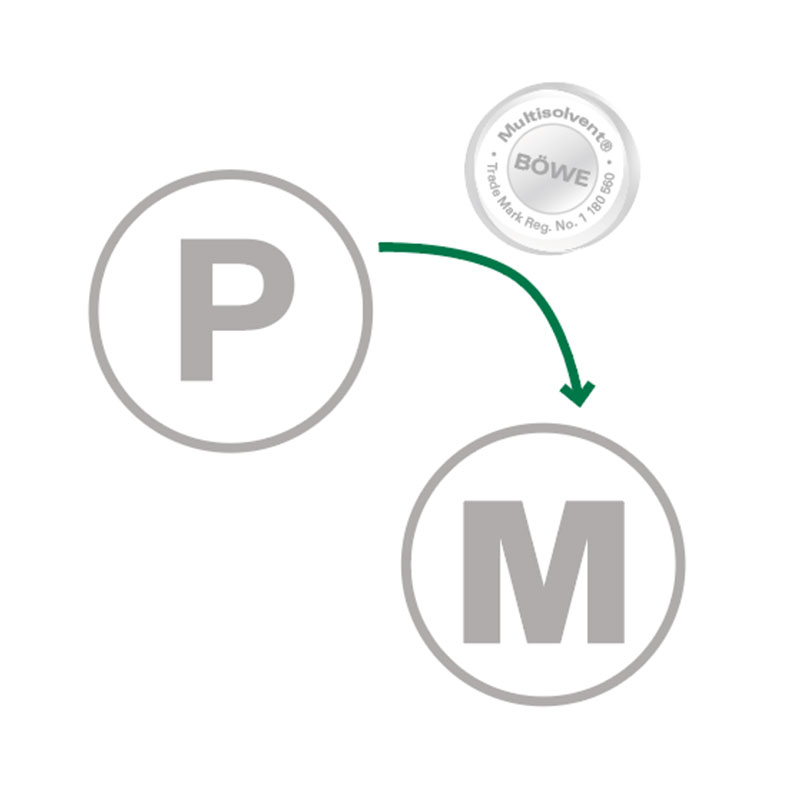

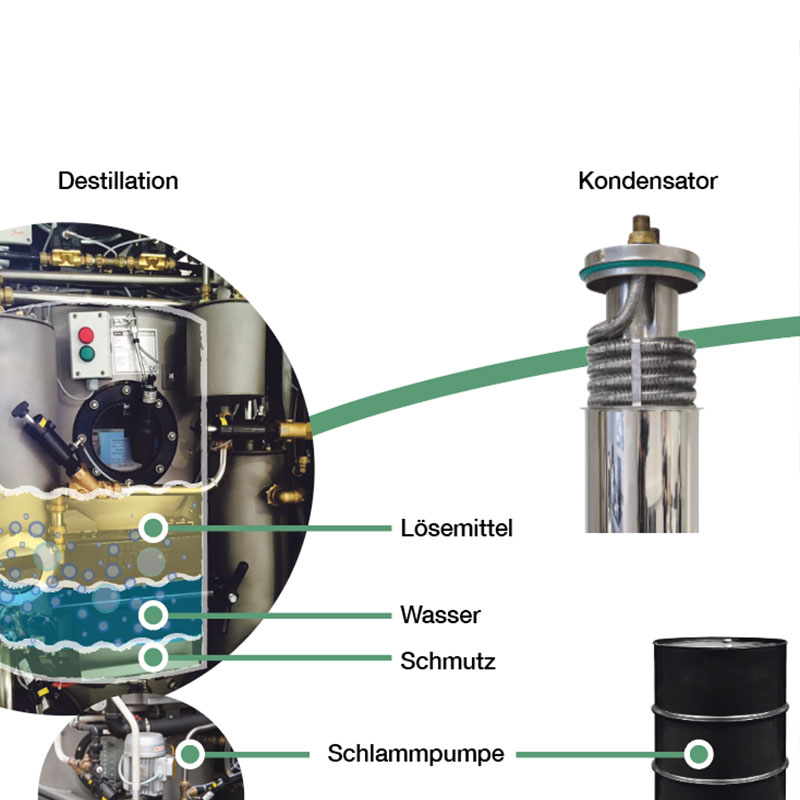

Combined with the Siemens control the degree of contamination of the garments and the solvent is measured optically with a glass fibre light guide. With the aid of the measured contamination, the solvent of the first bath is pumped to distillation in the case of strong turbidity (first picture). At low turbidity, the machine decides independently to pass on to the second bath (second picture). In this case, additional solvent is pumped up to a high level and then passed back through filters into the work tank. The dry cleaner can himself set the degree of contamination of the solvent via the computer control and thus determine when the machine is supposed to pump to distillation.

Further convincing technology

BÖWE dry cleaning machines, technologically and functionally sophisticated

WITH BÖWE DRY CLEANING MACHINES YOU CAN EVEN CLEAN DIFFICULT MATERIALS