Environment & Sustainability

BÖWE focuses on a sustainable development in both laundry and dry cleaning machines. We deal responsibly with limited resources and rely on future-oriented, environmentally friendly technologies.

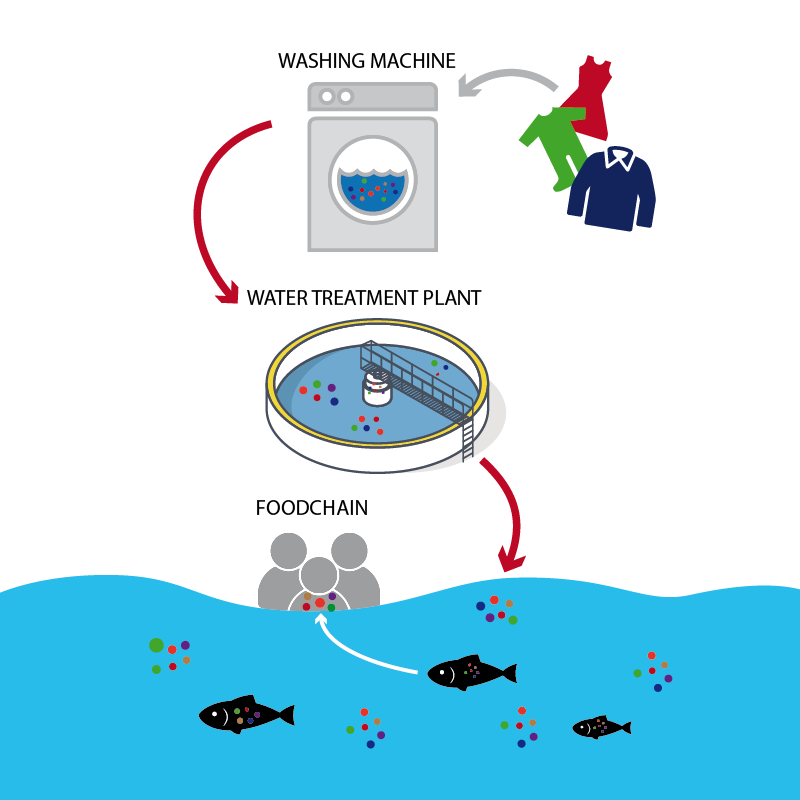

Abrasion of textiles

Microplastics are created by the abrasion during the washing of synthetic textiles. The microplastic particles enter the oceans via rivers and by direct discharge into the sewerage.

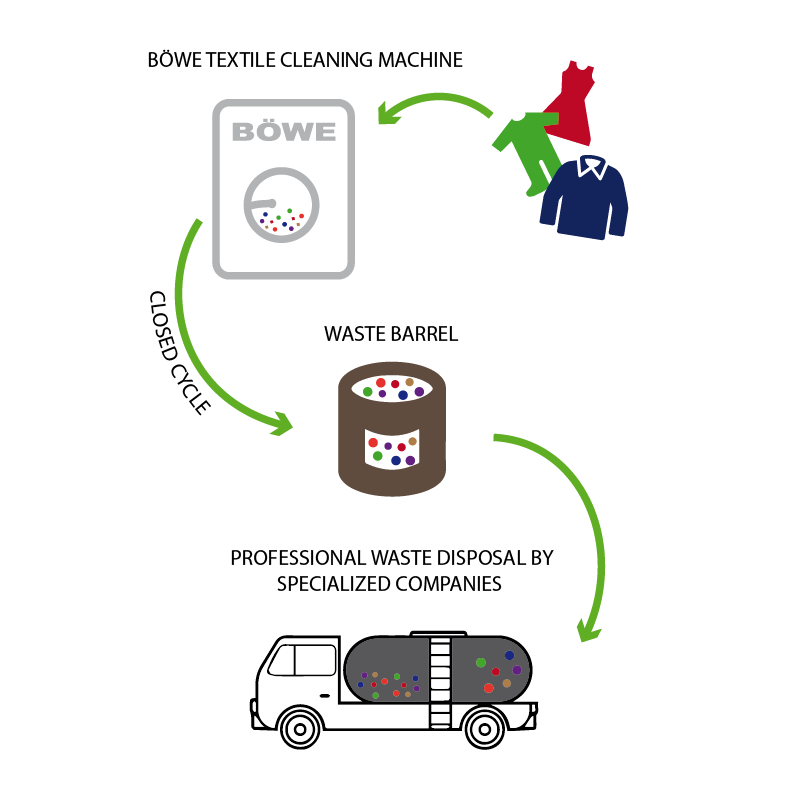

Through the closed cleaning cycle in BÖWE dry cleaning machines, the microplastic particles are collected in the distillation and disposed of separately. This means that they are not discharged into the sewerage, as is the case with a conventional washing machine.

BÖWE – closed cleaning cycle

The microplastic particles are collected in a container and disposed of separately.

Conventional washing cycle

The microplastic particles get into the sewerage with the

polluted water.

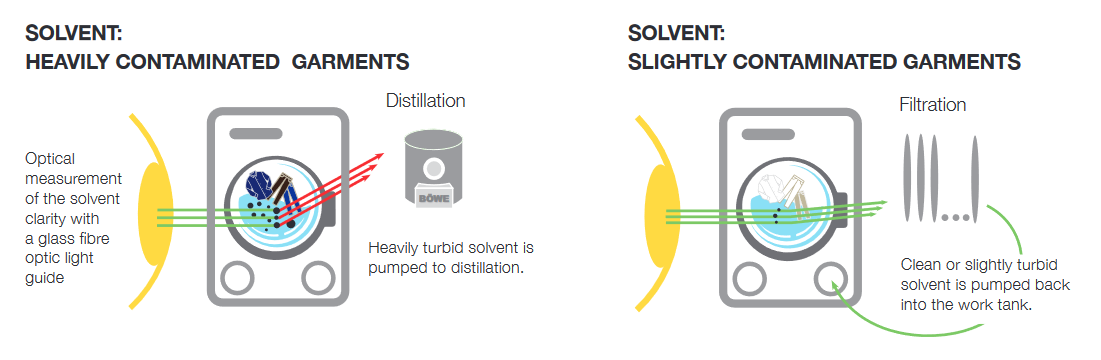

Turbidity measurement for clarity

BÖWE continuously strives for improving the energy efficiency of its already world class machines. Besides the low-level sensor that adapts the solvent quantity to the amount of garments, BÖWE developed another new energy-reduction feature in the area of environmentally friendly energy management: the automatic turbidity measurement.

Combined with the Siemens control the degree of contamination of the garments and the solvent is measured optically with a glass fibre light guide. With the aid of the measured contamination, the solvent of the first bath is pumped to distillation in the case of strong turbidity (first picture). At low turbidity, the machine decides independently to pass on to the second bath (second picture).