BÖWE Inspiring Solutions

Industrial supplementary products for your laundry and dry cleaning shop

BÖWE Water softener

Save time and money with BÖWE water softeners. Available with cabinet housing or as single or double unit.

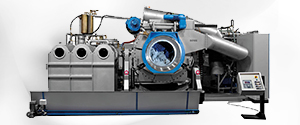

BÖWE Compressors

A clean and stable compressed air supply is essential for every dry cleaning shop. BÖWE offers different compressor sizes – also with refrigeration dryer and automatic condensate drain.

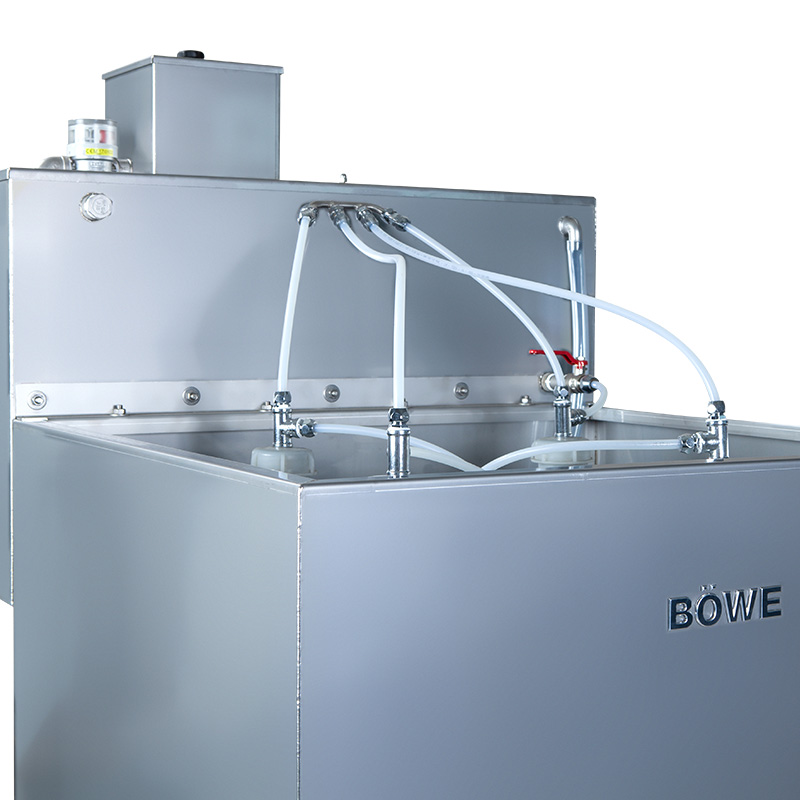

BÖWE Water collecting system

The BÖWE water collecting system is suitable for storing the cooling water from your dry cleaning machine and stores it for transfer to your wet cleaning machine. In this way, very little energy is consumed and you can save expensive water costs.

Optional: Additional tank with 1000 L and pipe connections

BÖWE Water chiller

The BÖWE water chillers are used to cool the cooling water of the dry cleaning machines in a closed system. In many locations, the use of a cooling tower is not possible or the use of drinking water for cooling purposes is prohibited.

BÖWE Water purifiers

For the safe separation of solvents bound in water

BÖWE Steam generator

With the new electric steam generator series, BÖWE offers low-maintenance and compact systems for the highest demands of the dry cleaning industry.

Optional: Blow down tank

BÖWE Hydro extractor

For mechanical reduction of residual moisture

BÖWE Vacuum units

BÖWE vacuum units ensure a strong vacuum on presses, ironing and spotting tables in your company. The vacuum units are offered for 1 to max. 20 machines, so that an optimal solution can be found for each application-specific case.

BÖWE Bagging solutions

Flexibility in dry cleaning shops and laundries – The BÖWE bagging solutions are available as floor, wall or L-sealers units and are equipped with manual, pneumatic or semi-automatic control.