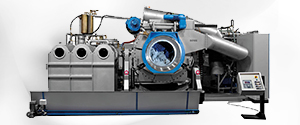

BÖWE PREMIUMLINE MULTISOLVENT®

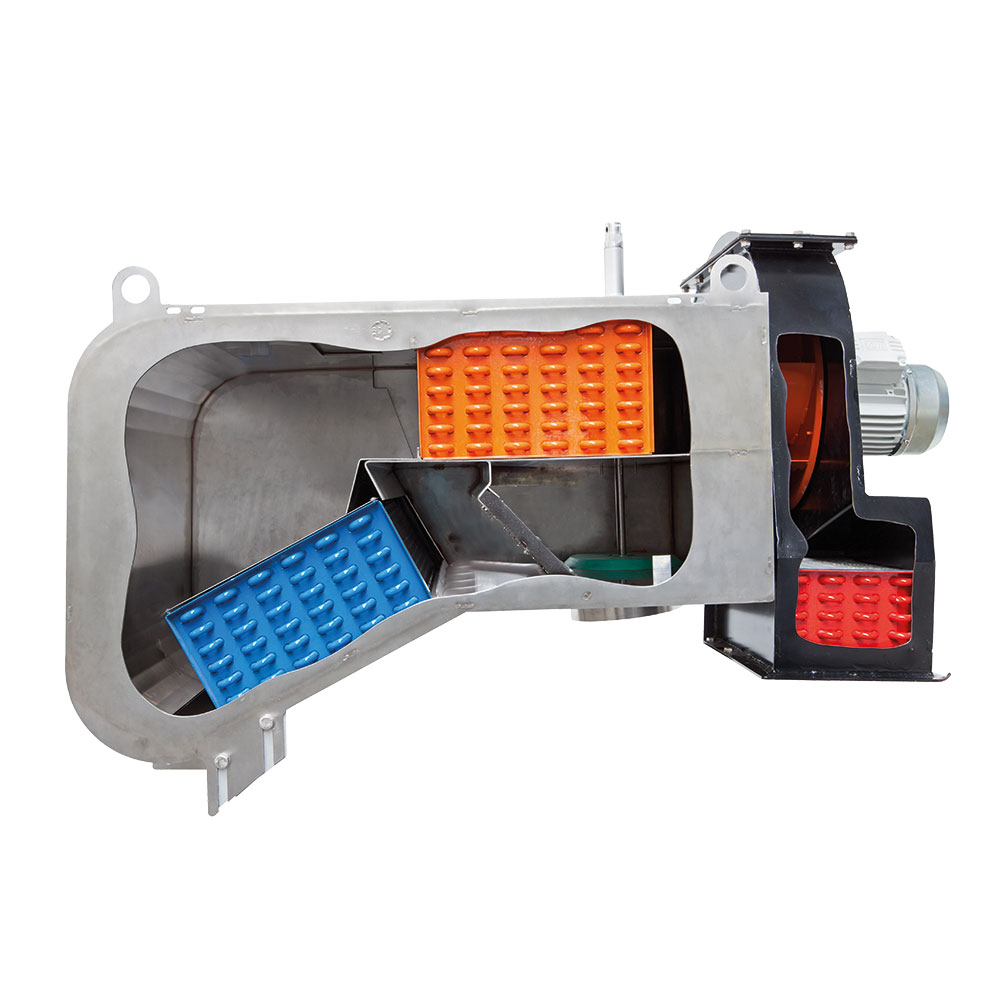

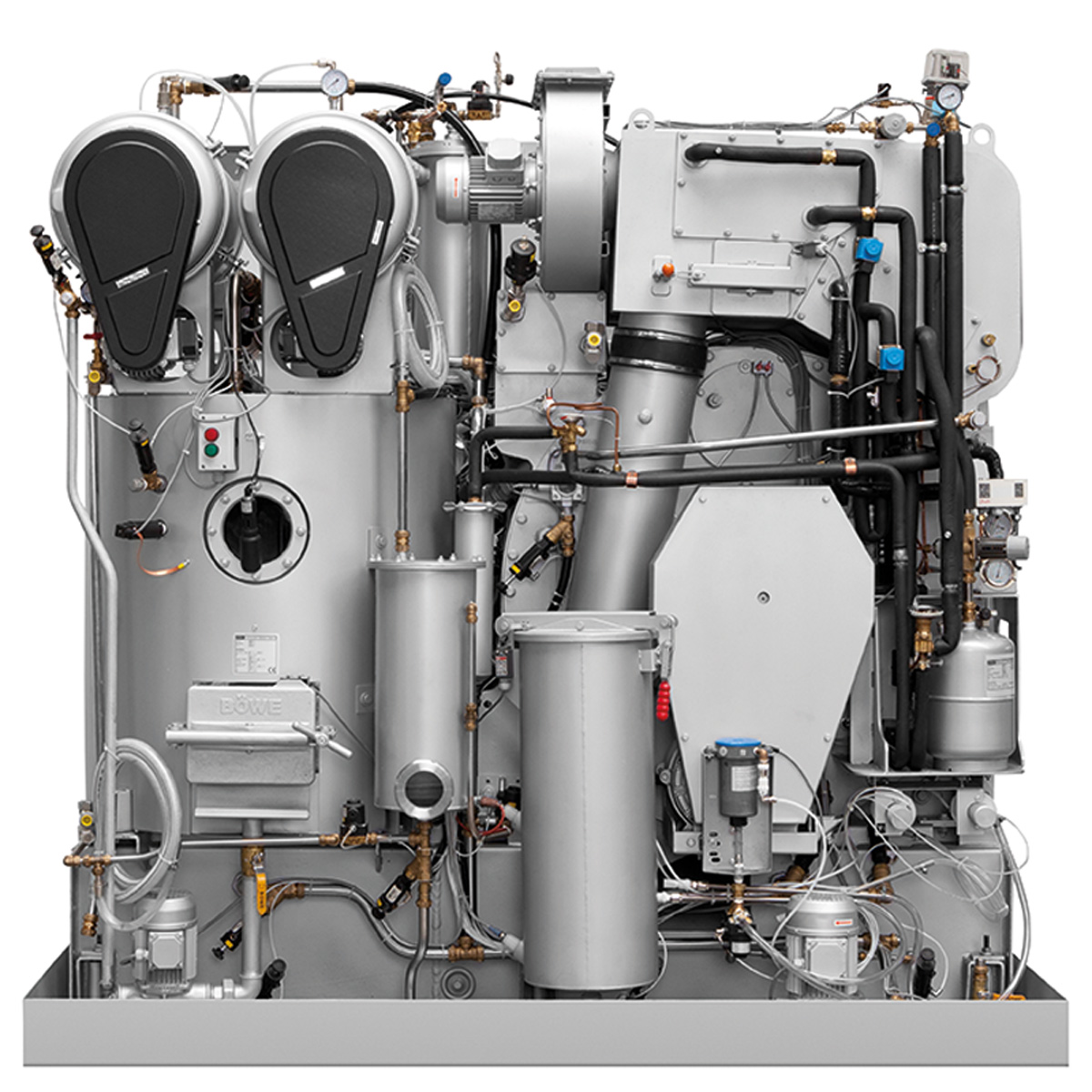

When developing the PremiumLine, we paid attention to the often limited space in dry cleaning shops. This is why our PremiumLine MULTISOLVENT® machines are available in two different versions: SlimLine and CrossLine.

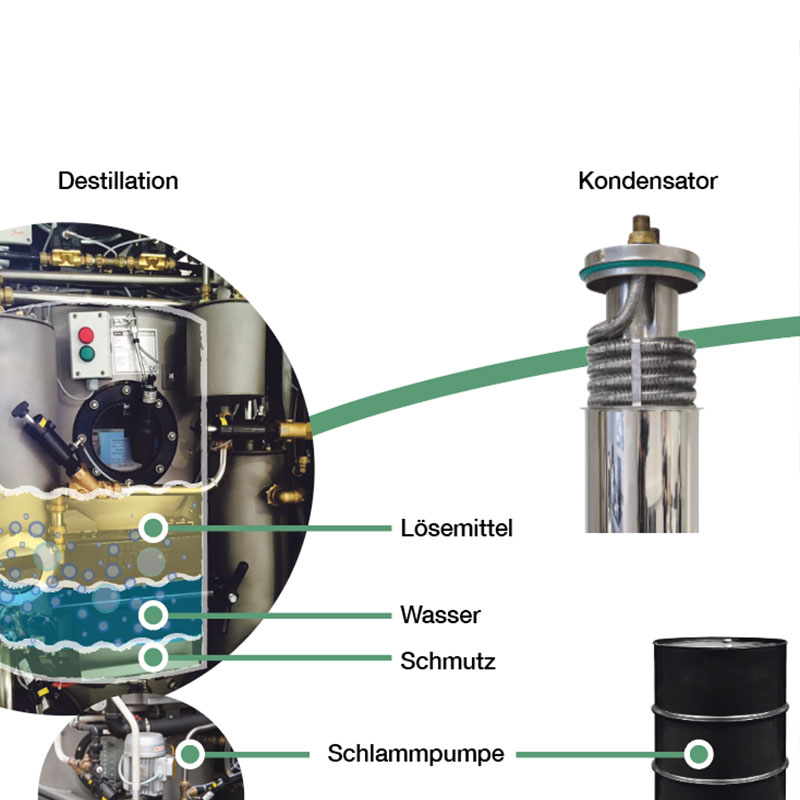

The SlimLine version has the distillation behind the drum module, in the CrossLine version the distillation is located next to the drum module. The insertion height of a SlimLine machine is less than 2000mm.

The PremiumLine MULTISOLVENT® machines are available with loading capacities of 12 kg, 15 kg, 18 kg, 21 kg, 26 kg und 30 kg. While the M12, M15 und M18 machines are available as Slim or CrossLine versions, the M21, M26 and M30 models are only available in the CrossLine version.

One machine – many solvent options

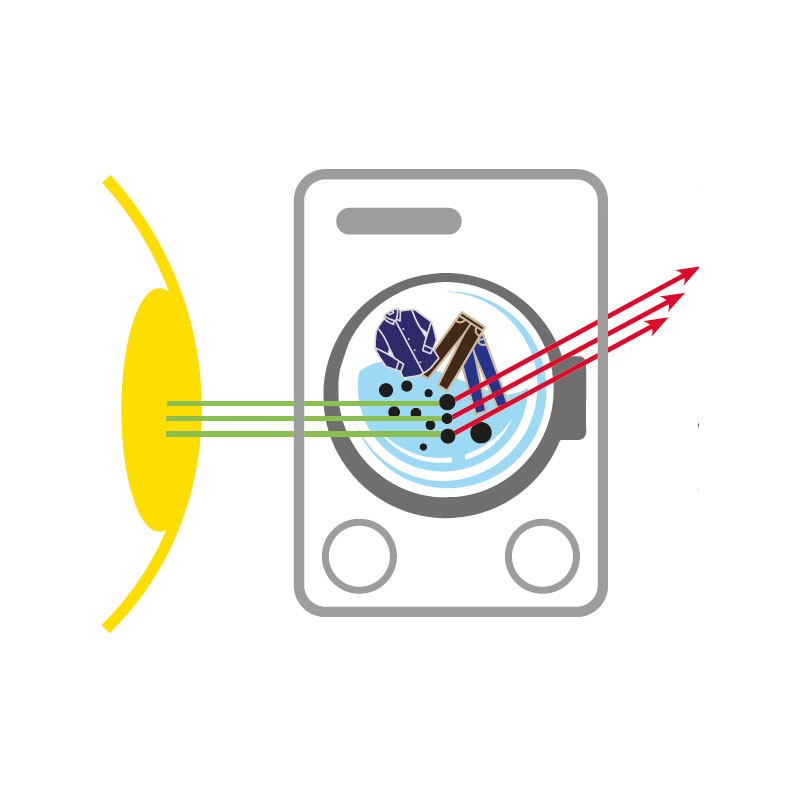

Due to the special design of BÖWE MULTISOLVENT® machines and the freely programmable computer control, it is possible to use the latest class A III chlorine-free solvents with a flash point above 55°C, which are lighter than water (e.g. HC, GreenEarth®, K4, Sensene, Intense, Higlo, etc.), in the machine.

Due to the special design of BÖWE MULTISOLVENT® machines and the freely programmable computer control, it is possible to use the latest class A III chlorine-free solvents with a flash point above 55°C, which are lighter than water (e.g. HC, GreenEarth®, K4, Sensene, Intense, Higlo, etc.), in the machine.

PremiumLine MULTISOLVENT® machines do not need mechanical conversions, but only a software update to change over from one alternative solvent to another. By simply changing the software settings, all functions and processes are adjusted to the solvent chosen.

With the P2M kit, a BÖWE PERC machine can be converted to a BÖWE MULTISOLVENT® machine.

QUALITY FEATURES BÖWE PREMIUMLINE MULTISOLVENT®

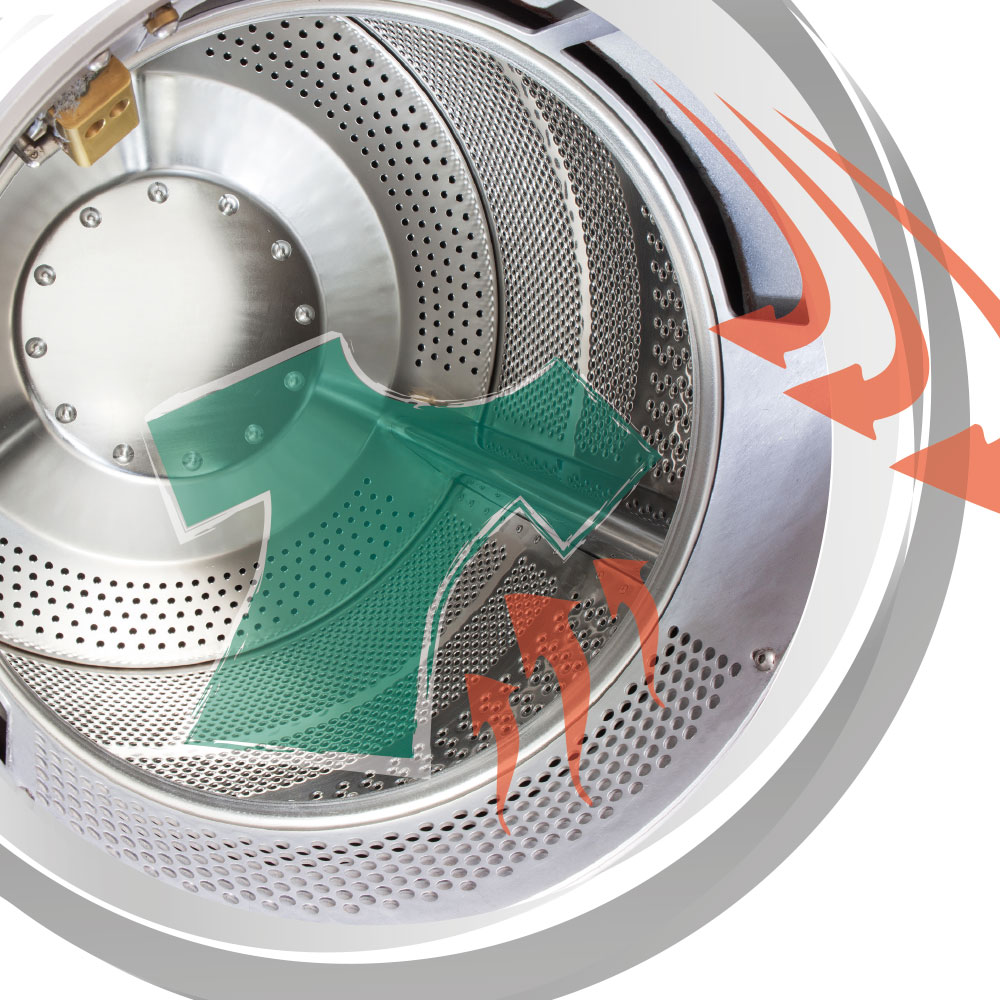

Outstanding characteristics

Technical data

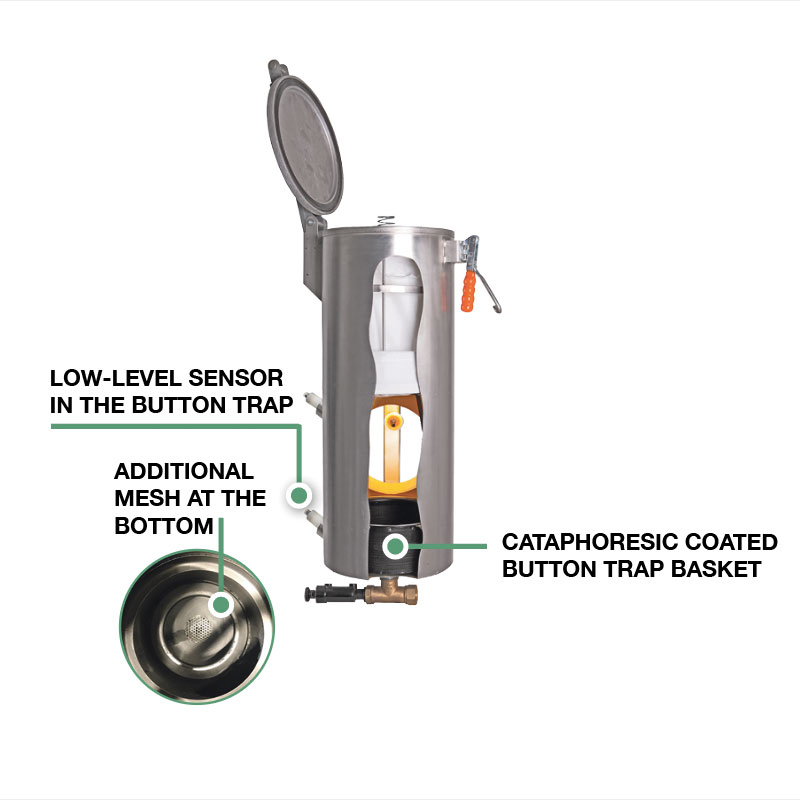

Further convincing technology

BÖWE dry cleaning machines, technologically and functionally sophisticated

WITH BÖWE DRY CLEANING MACHINES YOU CAN EVEN CLEAN DIFFICULT MATERIALS