BÖWE PremiumLine PERC

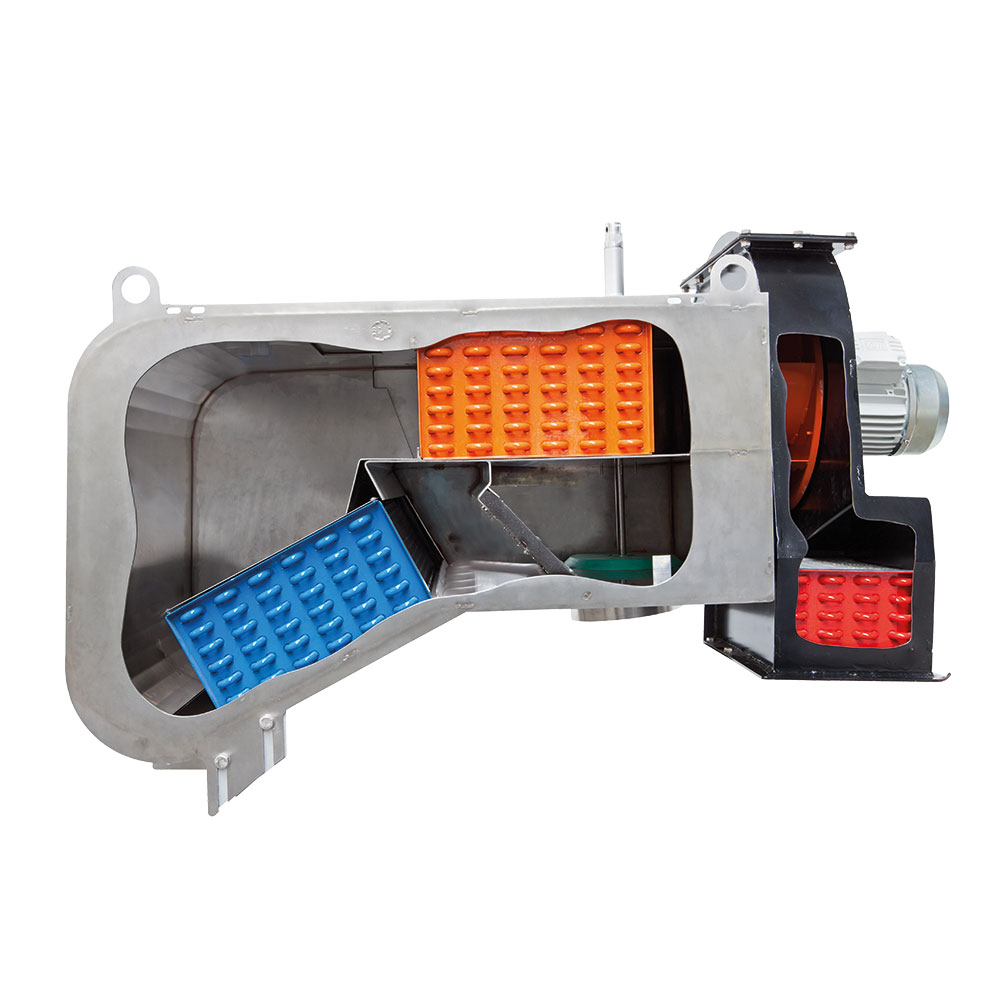

When developing the PremiumLine, we primarily had one issue in mind: The often limited space in dry cleaning shops. This is why these machines are available in two different design variants:

In the SlimLine version, the distillation is located behind the drum module, in the CrossLine, the distillation is located next to the drum module.

The PremiumLine PERC machines with 12 kg, 15 kg and 18 kg loading capacity are available as SlimLine and CrossLine versions, the PERC machines with 21 kg, 26 kg and 30 kg loading capacity are only available in the CrossLine version.

Ready for various kinds of use

The machines are available as a 3-tank-version and also with an optional second eco-filter and an additional carbon filter. Thus, you are extremely flexible, especially when cleaning different types of garments.

Compact

Even with special equipment like an emission free still rake out system or an optional adsorption unit SLIMSORBA, the machines remain very compact (insertion height of a SlimLine machine is < 2000 mm).

Easy maintenance

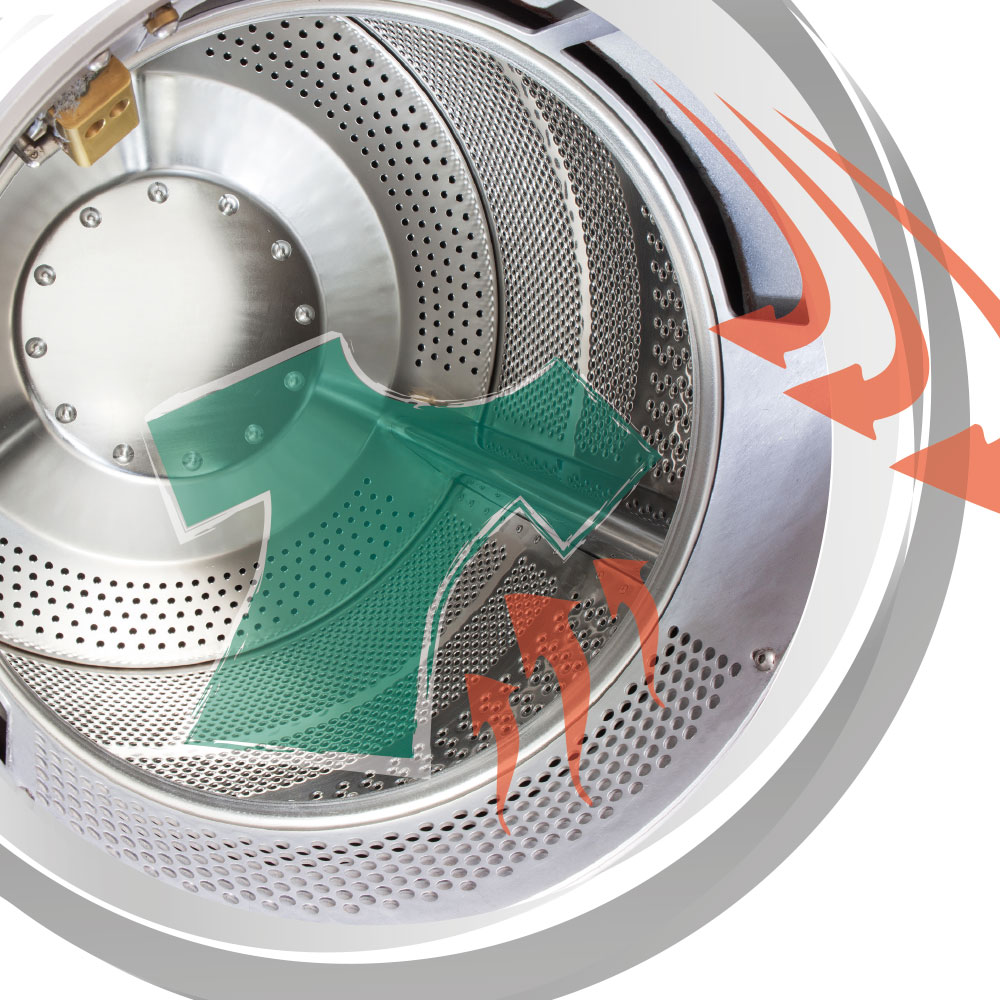

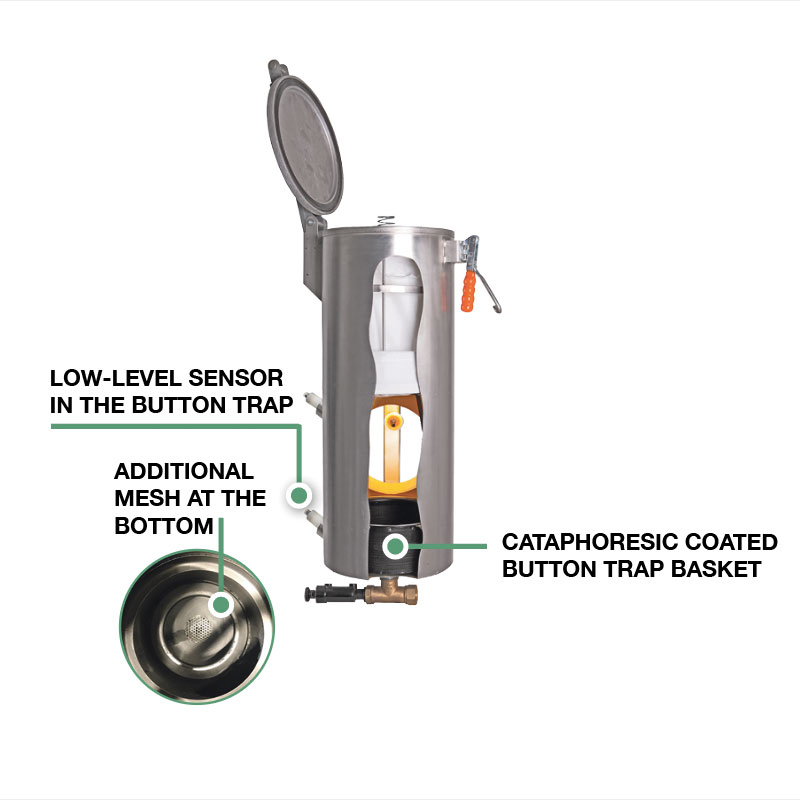

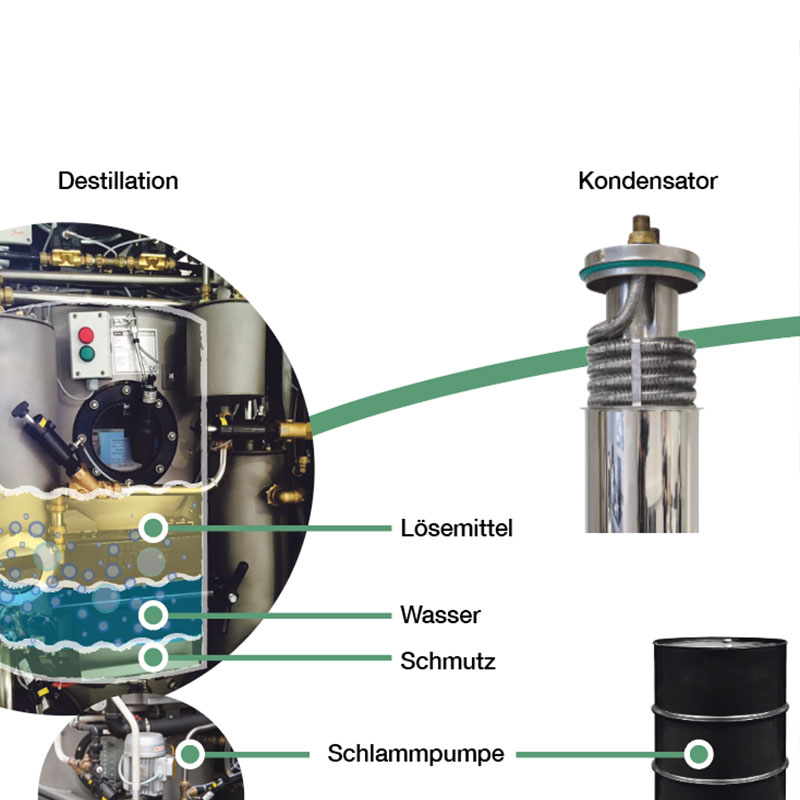

Only a machine that is well maintained is environmentally friendly. This is why we have made the rear wall of the drum easily accessible through inspection openings. Apart from that, the back plate of BÖWE machines is covered with a unique special coating, so that there will be hardly any lint clusters. The new water separator is self-cleaning and offers utmost comfort with maintenance by fully automatic maintenance programs. Thus, manual work is nearly not required. Distillation rake out is performed automatically and emission free, without the need to open the distillation. Furthermore, the solvent tanks are also self-cleaning thanks to a new tank geometry. Thus, smoother surfaces practically do not allow for any deposit anymore.

Comfortable control

The high-capacity control ConfoTronic PL offers a variety of possibilities for individual adjustment to various tasks and guarantees a safe, efficient and variable operation of the machine. The control can easily be updated by reading from a standard MMC or SD card.

BÖWE Direct Connect

With the BÖWE Direct Connect Software there is the possibility to work with the machine from a PC. You can retrieve daily, maintenance and operational reports locally or off-site and analyze them statistically. The system offers you and your service partner the cost effective and time saving remote diagnosis via telephone connection. Cleaning programs can easily be copied, edited, saved and loaded to PC or machine.

FURTHER OUTSTANDING FEATURES

Technical data

Further convincing technology

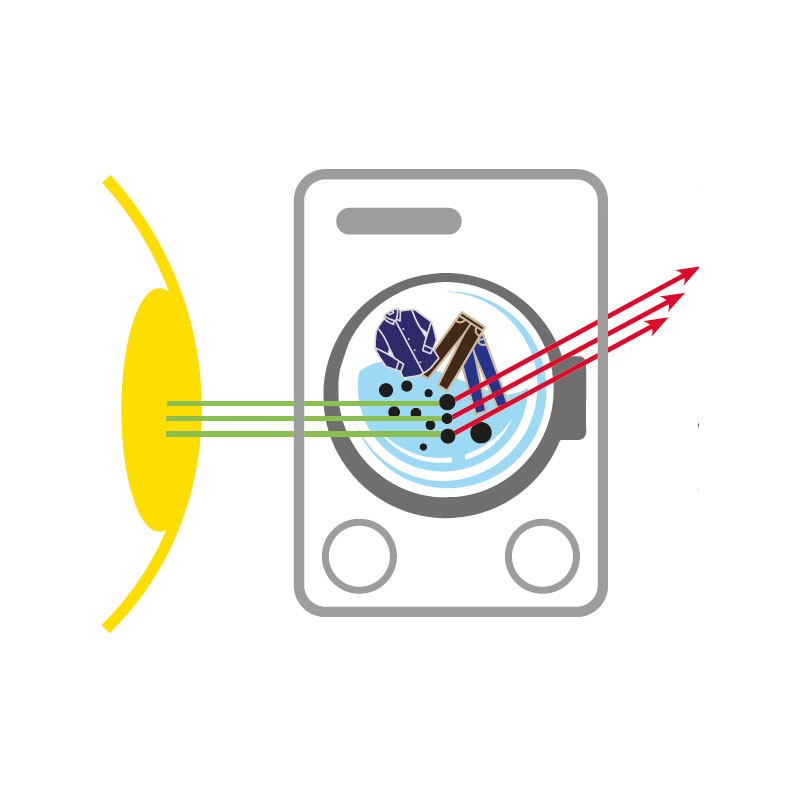

WITH BÖWE DRY CLEANING MACHINES YOU CAN EVEN CLEAN DIFFICULT MATERIALS