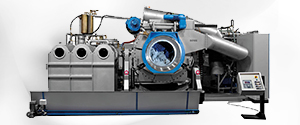

BÖWE SI70

Dry cleaning under the toughest conditions

BÖWE SI70 industrial machines have been extensively tried and tested worldwide under the most difficult conditions, e.g. with continuous use in a three shift operation. This obviously requires a high degree of reliability and durability, which BÖWE industrial machines offer with their extremely rugged design, using high-quality material combined with perfected technology. Their wide scope of use ranges from fur degreasing for the leather industry via workwear and gloves cleaning to carpets.

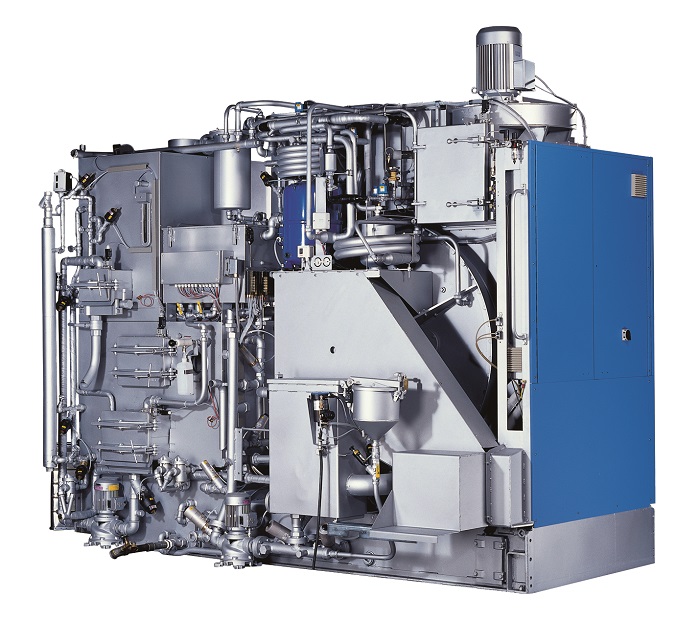

QUALITY FEATURES

Large condenser for a cooler solvent

Quiet and fast drying time

Low maintenance due to the special coating, little residue in tanks, etc.

Double distillation for cleaning goods with extremely high fat and oil concentration

Spraymatic pump with Viton® seals

Frequency controlled for high power transmission in low speed range

Emission-free solvent filling with integrated pump and high-performance solvent pump

Automated feeding hopper (can be selected as an option)

Technical data

| c-Model | i-Model | ||

|---|---|---|---|

| Solvent | PERC | PERC | |

| Cage | |||

| Loading capacity | kg | 70 | 70 |

| Cage volume | l | 1230 | 1230 |

| Cage diameter | mm | 1380 | 1380 |

| Cage depth | mm | 820 | 820 |

| Cleaning speed | 1/min | 28 | 28 |

| Extraction speed | 1/min | 340 | 340 |

| Tank volume (filling/total) | |||

| Tank I (work tank) | l | 350/430 | 350/430 |

| Tank II (clean tank) | l | 650/750 | 650/750 |

| Tank III (rinsing tank) | l | 350/430 | 350/430 |

| Distillation I | l | 750/1120 | 750/1120 |

| Distillation II | l | 350/700 | |

| Eco filter | l | 320 | |

| Operating load | kW | 26.7 | 26.7 |

| Distillation flow rate | l/h | 1100 | 1600 |

| Machine measurements | |||

| Width | mm | 3500 | 3500 |

| Depth | mm | 2290 | 2290 |

| Height | mm | 3100 | 3100 |

| Floor Space | |||

| Surface | m² | 5.0 | 5.0 |

| Width | mm | 3500 | 3500 |

| Depth | mm | 1430 | 1430 |

| Weight | |||

| Weight (without solvent) | kg | 4480 | 4980 |

| Floor Load | |||

| static + dynamic | N/m² | 21000 | 22000 |

Outstanding characteristics

WITH BÖWE DRY CLEANING MACHINES YOU CAN EVEN CLEAN DIFFICULT MATERIALS